Electric motors are essential in powering a range of equipment used for industrial and commercial applications that not only drive smooth operations but improve efficiency & productivity as well. This 3 to 4 HP single phase electric motor is a type of library among many types in the cataloged collection, and it encapsulates everything that an average person might ever need for driving loads, from farming tools e.g., grinders or feeders to shop machines like saws. They are the original installation and maintenance-friendly motors that strike a fantastic balance between power, they will impress even in XYZ CNC machines as well with simplicity which makes them favorable among small-medium enterprises & people who love doing things themselves. In this deep dive into the 3-4 HP single phase electric motors vital for numerous working applications, we identify just what distinguishes these beauties from all others selling briskly in droves wondering buyers to select their most fitting choices as well and even providing a focus on energy-saving functions revealing secrets behind why they last so long while operating almost whisper-light sounds every time you pull that plug. Plus uncovering top-secret reasons premium models will always purchase without going back again with some true-to-form technological offerings unmatched by any other mere mortal based product creation out there today!

The best motors in this class will typically be those that have the highest efficiencies, starting torques, and build qualities. High-efficiency designs, such as motors utilizing copper windings and precision-engineered rotors are recognized to offer premium performance while simultaneously reducing energy lost. Tasks requiring immediate load-handling (ex-moving items on conveyor belts; powering compressors) need motors with high starting torque. In addition, they are equipped with motors engineered for continuous duty cycles that offer consistent performance without overheating further highlighting their robustness and handling of difficult tasks.

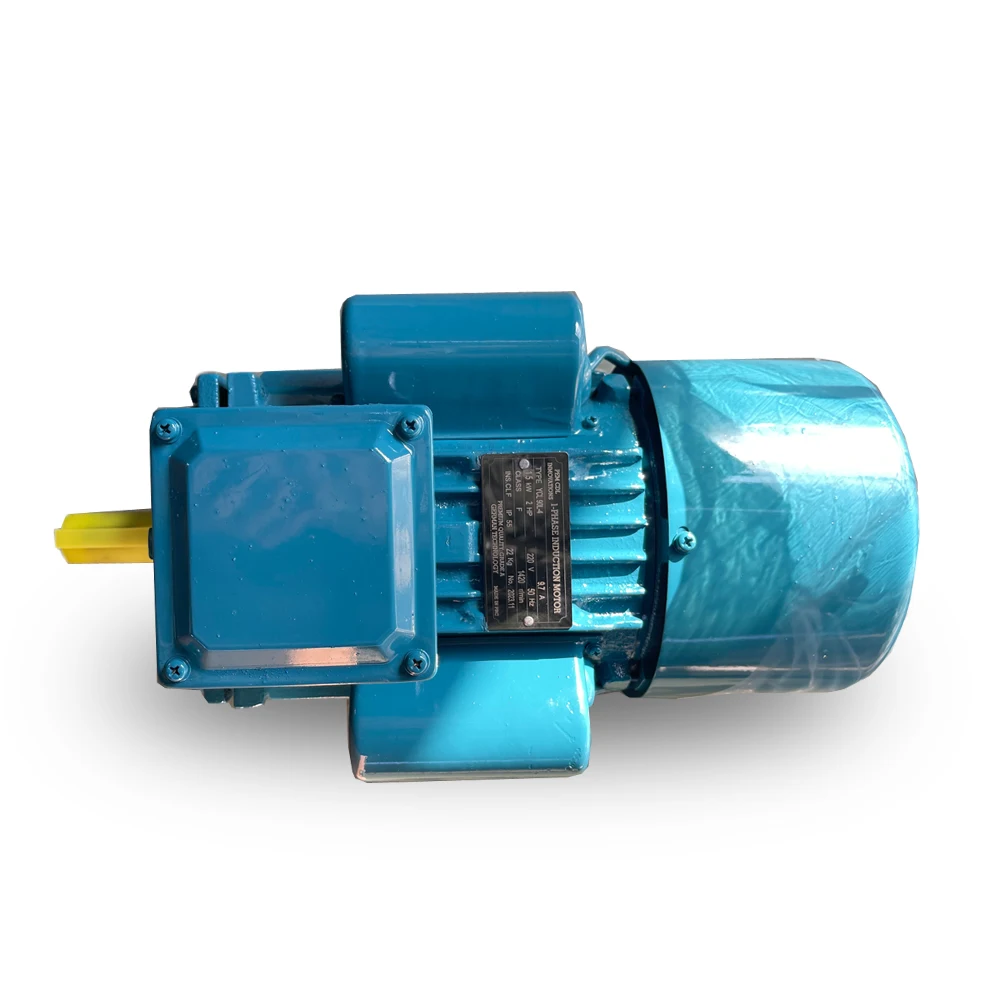

If you buy a 3-4 HP single stage motor, make sure that it is compatible with your current electrical setup. Make sure to check the voltage requirement of your motor (usually in 230V range but it can be different, which also needs to have same phase of power supply as that for motor) Also, what type of load the motor will be driving (constant power, variable torque or maximum starting currents). Weatherproofing a motor with an appropriate enclosure rating - such as TEFC (Totally Enclosed Fan Cooled) to protect the interior components of a designed motor against exposure to dust and moisture, particularly in harsh environments. Also, the IP rating for dust and water protection is important. Finally, you might even want to think about after-sales support and warranty terms as these have an important effect on long-term satisfaction in addition to cost-effectiveness!

Improved motor technology has enabled the creation of energy saving models which utilize less enough electricity throughout operation, thereby improving overall operational efficiency. And electronic commutation systems help getting rid of traditional brushes, thereby friction and energy lose is lessened. To save even more energy, many motors have variable frequency drives (VFDs) which can be used to adjust the motor speed based on what is demanded by the application at a particular time. Meanwhile, advanced cooling enhancements like improved fan designs keep the motor in an ideal temperature window as it runs which stops extra power consumption from producing heat. As a result of these improvements, it can be directly cost-effective and has reduced emissions.

Through careful engineering and using only quality components, the high noise levels produced by these motors can be reduced to near-silent operations. High-quality materials and components such as sealed ball bearings decrease friction and erosion, which supports a long service life of the motor. Housing: metals, or composites offer strong protection from physical damage and the corrosive elements found in fuel. Unique insulating methods save the windings from warmth and electric strain, increasing motor existence. In addition, the use of dynamic rotor balancing and motor design with tight air gaps help reduce vibrations in order to keep it running smoothly. These motors also feature special coatings on the moving parts to keep noise levels very low making them ideal for quiet applications.

electric motors superior performance, environmental friendliness quiet operation. They 3 4 hp single phase electric motorto be customized to suit your specific needs.

Yongzhuan been recognized by CCC, CE and other certifications. Furthermore, owns over 40 patents including for our 3-phase electric motor that are covered by independent intellectual property rights. It was named a high-tech enterprise within the province of Jiangsu Province. We make use of only the highest 3 4 hp single phase electric motorraw materials, we have a reliable supply chain in place ensure that our products meet every customer's needs. Take advantage of a broad range of fast and cost-effective international shipping options, which ensures speedy delivery all customers worldwide.

Yongzhuan Motor a full-service manufacturing design company with 25-years experience. facility covers 10,000 square metres and annually production of 3000,000 motors. extensive production line together with our state-of-the art quality inspection equipment will ensure that electric motors we produce are of the highest quality. Yongzhuan a sturdy engineering and design force. Two production lines are automated and robots with intelligent capabilities are utilized. 3 4 hp single phase electric motormotor performance testing equipment includes over 10 sets. group of 20 expert motorists and engineers is committed to providing the latest solutions. can trust the reliability and quality of motors, since they're certified with CCC and CE marks, ensuring conformity to international standards.

Yongzhuan manufactures mainly the three-phase YE3 high-3 4 hp single phase electric motorinduction motors, YBX3 explosive-proof induction motors, gear motors gearboxes, gear reducers other custom motors. products are certified by 3C, CE third-party quality tests. products are generally exported to the United States, Germany, Japan, Italy other many nations regions. vast inventory allows us deliver items quickly and guarantees short lead times for customized electric motors.